Johnson Controls Peak

Demand Control Ventilation (DCV) controllers integrate with the building ventilation system to modulate the amount of outdoor air based on input from a CO2 sensor. They can be used to save energy during low occupancy and improve indoor air quality during high occupancy.

Learn MoreIf you are experiencing issues with the comparison tool, please disable your adblocker.

Johnson Controls Peak

Ventilation controller with economizer with available inputs for CO2-based demand control ventilation capabilities.

Hub Highlights:

- Monochrome LCD display and buttons for commissioning, troubleshooting, or viewing status.

- BACnet MS/TP supported.

- Good performance under Hub simulated occupancy profiles.

- CO2 Sensor Compatibility Universal – Works with any CO2 sensor that has the ability to output compatible signal

Last Edited on: Jul 26, 2022

| Model Number | PK-ECO1001-0 |

| Power Supply | 20-30 VAC, 50/60 Hz |

| Controller CO2 Sensor Input Signal Types | 0 to 10 VDC, 0-2000 ppm Analog |

| Actuator Signal Output Types | 0-10 VDC or 2-10 VDC |

| Nominal Power Consumption | 15 VA. Does not include any sensors or actuators |

| Economizer Control Options | Single dry bulb change over; Single enthalpy change over; Differential enthalpy change over |

| Other Inputs | Additional analog inputs include the supply air temperature, outdoor air temperature, outdoor air humidity, return air temperature, return air humidity, building pressure input, outdoor air flow, and damper feedback position. Additional binary inputs include first cooling stage status (Y1), second cooling stage status (Y2), heating stage status (W1), shutdown status, purge status, and occupancy status. |

| Other Outputs | Additional binary outputs include alarm output, first cooling stage command (Y1), second cooling stage command (Y2), and exhaust fan output |

| Controller Configuration Method | Local (display) |

| Controller Response to CO2 Sensor Failure/Power Loss | The controller logic is reconfigured to ignore DCV settings. DCV settings are maintained in memory and restored when power is restored. Controller defaults to economizer mode. |

| Manufacturer Reported Control Algorithm Details | A Pattern Recognition Adaptive Control (PRAC) algorithm tunes Proportional-Integral (PI) feedback loops |

| Supported Communication Protocols | BACnet MS/TP communication |

Last Edited on: Jul 26, 2022

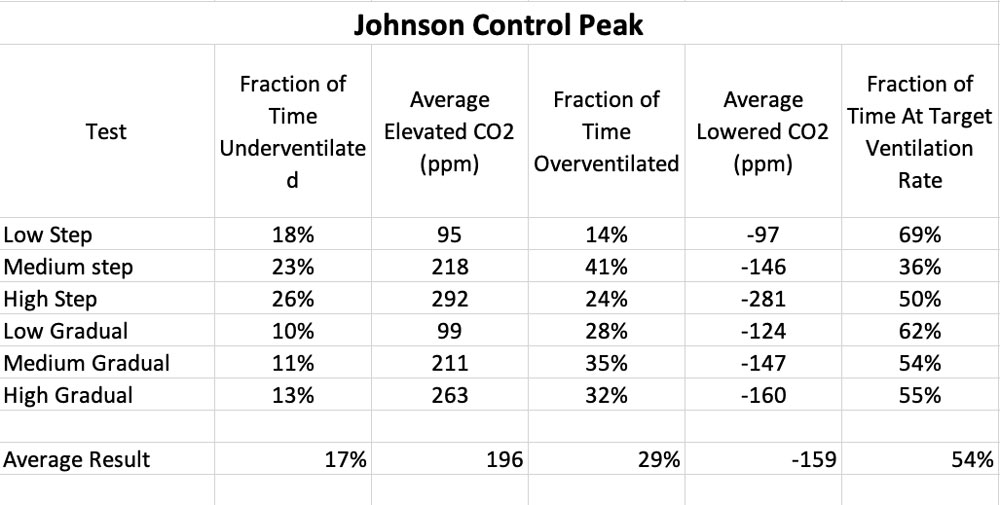

| Date of Test | March 2021 |

| Number of Tests | 6 |

| Setting | N/A |

| Average Fraction of Time Underventilated | 17% |

| Average Elevated CO2 During Underventilation (ppm) | 196 |

| Average Fraction of Time Overventilated | 29% |

| Average Lowered CO2 During Overventilation (ppm) | -159 |

| Average Fraction of Time At Target Ventilation Rate | 54% |

| DCVC Full Results | See Table |

Last Edited on: Jul 26, 2022

User interface

Describe interface for commissioning.

Display and buttons on device

User interface

Describe the settings for the device.

Minimum damper position, maximum damper position, setpoint

User interface

Does the controller have alarm capability to notify facilities of a problem? If yes, describe.

Yes - Alarm information is stored on the device. Alarm flashes LED on device. Alarm switch (dry contacts) can be connected to building automation system.

Installation

Does the controller require specialized software for installation? If yes, describe

No

Installation

Does the controller require specialized training for installation? If yes, describe

No

Installation

What is the resolution for CO2 setpoint?

By 10's

Installation

How is damper position specified?

Percentage

Installation

Can the CO2 sensor be universal or manufacturer specific?

Universal

Installation

Can you specify sensor calibration to correct for sensor error in the DCV system controller?

No

Integration capabilities

Can the controller interface (beyond dry contacts) with a building automation system (BAS)? If yes, describe if integration capabilities are vendor specific.

Yes - Proprietary equipment only

Integration capabilities

If the controller can interface with a BAS, is additional hardware required? If yes, describe.

Yes - Multiple proprietary options available

Operation

Does the controller require on-going maintenance? If yes, describe?

No

Operation

Does the controller require service contracts for ongoing data access? If yes, describe

No

Integration capabilities, Reporting capabilities

How can the controller data logged? If proprietary software, describe (what type of account is needed, what logging intervals are available, what does it look like, and describe its capabilities including data download capabilities).

Through BMS if installed